Offshore hydrogen plans require development to support the decision making process, we are well aware of these processes. In brief our services are as follows:

Electrical System Studies and Design

Offshore hydrogen starts at the integration with the Offshore Wind Park (OWP). The production if hydrogen requires a suite of different components to convert the large power at high voltage to low voltage for electrolysis. Our services typically include:

- System design, arrangements and optimum schematics (SLD)

- Wind resource assessments with system efficiency studies

- Load Flow Analysis for component and cable sizing

- Electro Magnetic Transient (EMT)

- Off Grid (micro grid) or grid compliance studies

- Platform / room lay-out and design

For a variety of projects we have completed or are in the process of completing studies to support clients in their project evaluations.

Process System Studies and Design

The hydrogen production process requires treatment of hydrogen for export, with potential of compression. Next to that a wide variety of utilities are required in terms of (sea)water treatment, cooling, venting and purging. Some of these systems directly tie-in to the environmental objectives for low to zero emissions. Our services typically include:

- System design, arrangements and optimum schematics (PFD, P&ID)

- Heat and mass balance calculation to support sizing of piping and equipment

- Dynamic modelling for wind following operation

- Equipment specification and selection

- Platform lay-out design and detailed piping design

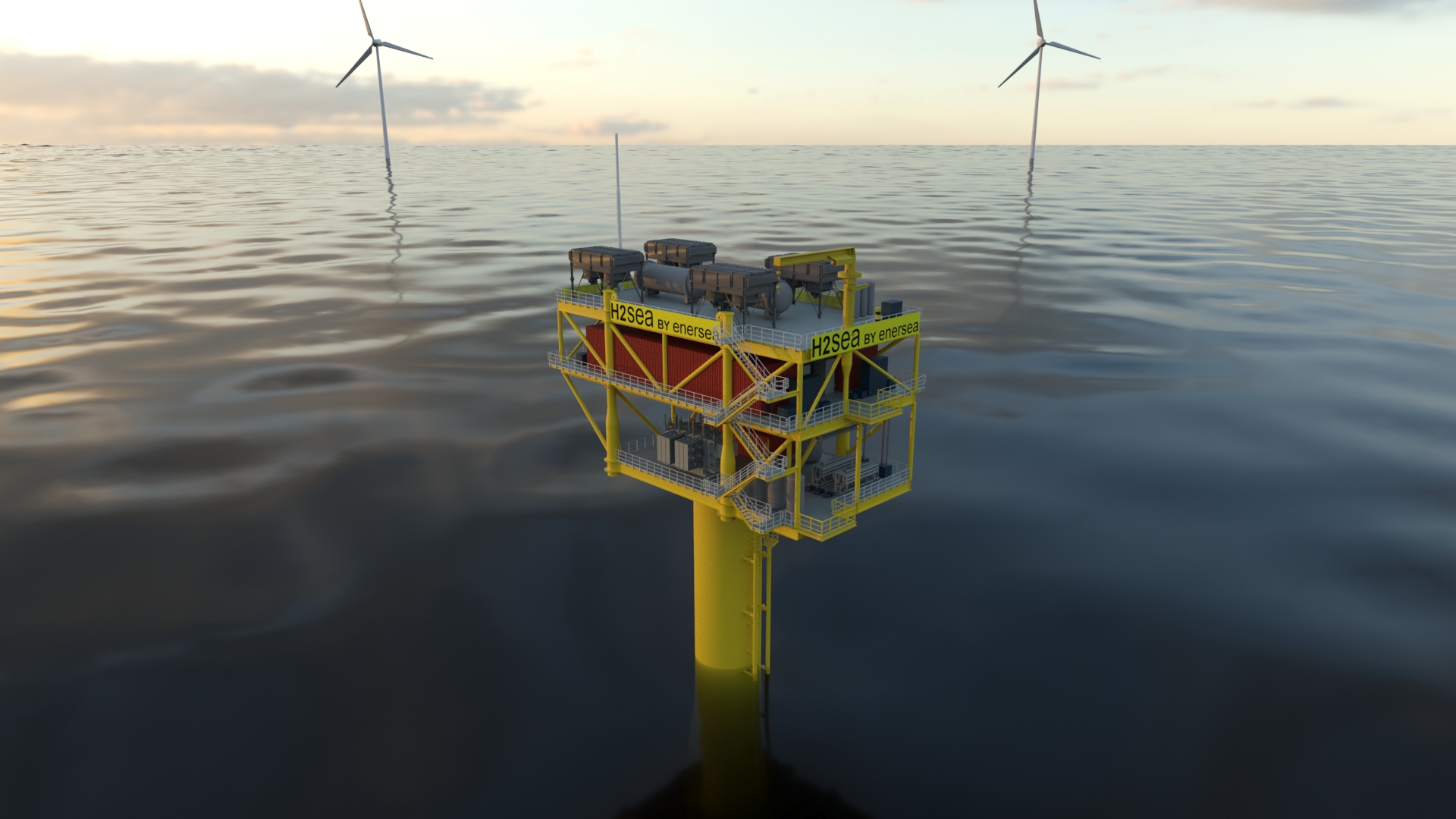

Platform Structural Design

The large variety of equipment and systems with each of their specific operations and maintenance requirements of the long life time are packaged in either a single of multiple modules. For the specific hydrogen development choices may need to be made between a modular or bespoke topside design incorporating available installation vessels. Our services include typcially:

- Lay-out development in combination with mechanical handling studies

- Topside primary, secondary and tertiary steel design in parametric software (TEKLA)

- Foundation design of monopiles or jackets with their respective soil interaction (SACS)

- J-tube and riser design integration

Field and Subsea Design

Hydrogen developments require pipeline export of the product which directly interacts with the field lay-out for cables and potential existing infrastructure. Through our offshore back ground we are able to provide a full design package for pipelines with routing to comply with regular offshore standards in NEN, DNV, BS or Norsok.

Project Delivery Management

Each phase fo a project requires a different approach, at H2SEA we have the specialists in house to guide a project through the different project decision stages of identify, select, define (FEED) and execute. Eventually we we deliver up to start up after hook up and commissioning (HUC). Our services typically include:

- Engineering management

- Client and Stakeholder engagement through workshops, specially in the select phases

- Cost estimating (CAPEX, OPEX, ABEX) and associated cost risk analysis

- Planning and project scheduling including schedule risk analysis

- Engineering, Procurement, Construction and Installation Management (EPCIm) with one of our partners.

Please reach out to us, as the above list is maybe only an initial summary of our services.